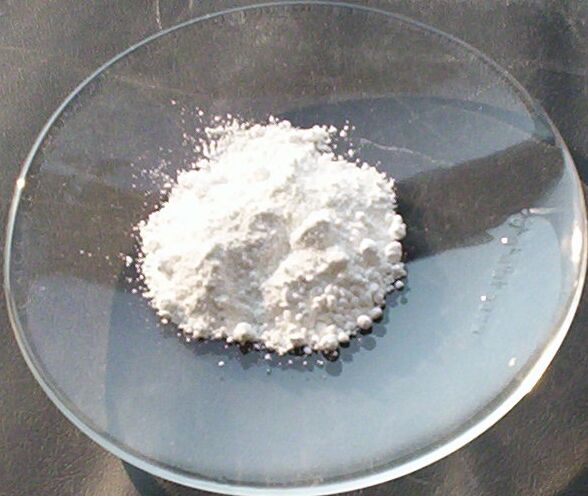

Role Of ZnO Additives For Rubber In The Rubber Industry

The rubber industry alone is responsible for consuming up to 2.5 million tons of the filler function. The use of zinc oxide additives for rubber by the rubber industry is calculated at a whopping 60% to 70% out of the entire lot. The main use of the additives goes into the formulation of rubber. It is pretty important to understand how the role of Zno additives for rubber plays an important role when the process of vulcanization is concerned.

Understanding the Use Of ZnO Additives For Rubber In The Industry

The process of vulcanization includes the chemical process whereby the conversion of polymers into materials that are durable in nature takes place. This chemical process occurs when cross links are introduced. A very common example of vulcanization process is to look at the vulcanization of sulphur. Here, all of organic polymers are linked with the aid of the sulphur chains. These cross links which gets formed among the entire polymer chains tend to bring about a drastic change in the mechanical properties during the process of vulcanization in the polymers.

Zinc Oxide plays a major role when the formulation of rubber is actually concerned. ZnO additives for rubber tend to have gained quite a reputation in the last few years mostly because of its advantages. The rubber materials which include the elastomers along with the amorphous polymers are actually mixed along with the components which results in a more complex compound. This entire process results in vulcanized rubber. There are a number or rubber products which can be stretched to great lengths without letting any distortion form to the original form.

If one were to compare rubber to steel, then the former is definitely resistant to abrasion than the latter. When rubber is put inside different solvents, the original form remains intact due to the fact that it mostly remains quite prone to most of the chemical corrosion. The widely used commercial rubber material includes polyisopre which is quite renowned as a natural kind of rubber. Polybutadiene rubbers, styrene-propylene rubber, rubber etylenpropylendien, along with many others tend to fall under the category of synthetic rubbers.

The process of condensation of the unsaturated hydrocarbons tends to produce synthetic rubber. The commercial synthetic rubber comprises of many components such as neoprene, buna, butyl rubber et cetera. In the rubber industry the role of zinc oxide is also majorly seen as an activator or an accelerator.