Why High Temp Bearing Grease Vital For Lubrication Purposes?

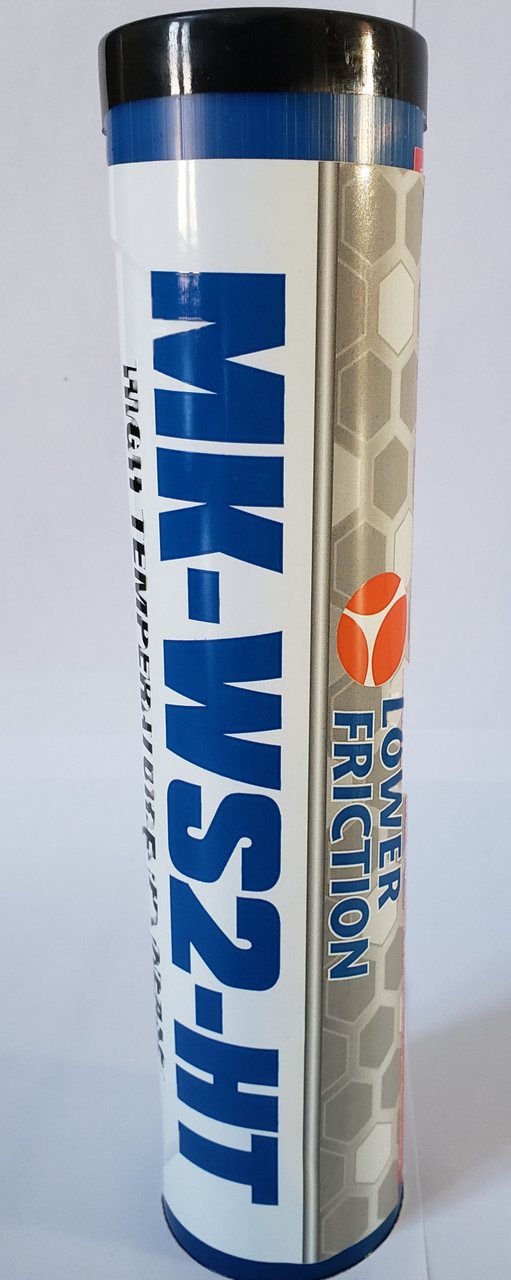

High Temp Bearing Grease | cdn11.bigcommerce.com

Among the various forms of lubricants that are available in the market, grease is popular due to its enhanced thickness. It turns out to be a mixture of soap base and mineral oil providing it with a certain type of viscosity. Hence it is pivotal that you go on to check out the dropping point associated with any form of grease on how effectively it works if the temperature is on the higher side. The grease would be influx with various forms of additives, that are going to enhance the properties and make it considerably powerful.

In the market, there are numerous forms of lubricants and the choice becomes a difficult task. It is necessary to have an idea about the properties of the lubricant so that the correct decision can be made. An example is that you may require some form of lubricant if the temperature is on the higher side. In this case, you can go on to choose a high temp bearing grease that is going to remain stable in all scenarios. Now in this case it would be better that you go on to choose a grease that is a semi-solid lubricant.

High temperature bearing grease and its features

The composition of grease involves a thickener and a base oil. The base oil may be in the form of synthetic oil or mineral oil. This encompasses around 75 % to 90 % of grease. On the other hand, the thickener is available in the form of a metal soap or else it may turn out to be in the form of a non-soap thickener. Normally it is available in the form of 3 % to 30 % grease and 10% are additives that have a major bearing on the manner by which it works. Below are some of the benefits associated with a high- temp bearing grease.

• The moving parts can slide against each other, without causing any form of issues

• When the machine is operational at a high temperature, one of the better ways to protect it is to be using high-quality grease

• After you apply it this would remain for a considerable period of time that is known to provide an enhanced form of lubrication onto the moving part that is operational at an optimal level.

• In places where oil cannot be used it turns out to be the best lubricant

• There may arise a situation where lubrication of the metal components cannot occur regularly or else it has to be sealed so that the grease may work

When it is the room temperature the grease may remain in a solid form but the oil may be available in a liquid form.