Coat Machine Parts With WS2 Dry Lube For Smoother Performance And Higher Output

Features WS2 Dry Lube | cdn11.bigcommerce.com

One of the most important dry lubricants is tungsten disulfide, which is often used in situations where it is not possible to make use of molybdenum disulfide. Such versatile usage of this dry lubricant is possible only because of its superior lubrication properties, for which it is in high demand. You might want to use graphite or perhaps molybdenum disulfide but find that their properties do not suffice. It can be easily mixed with other dry lubricants, such as grease and oil, as well as synthetic lubricants.

WS2 Dry Lube Features That Set It Apart From Other Dry Lubricants

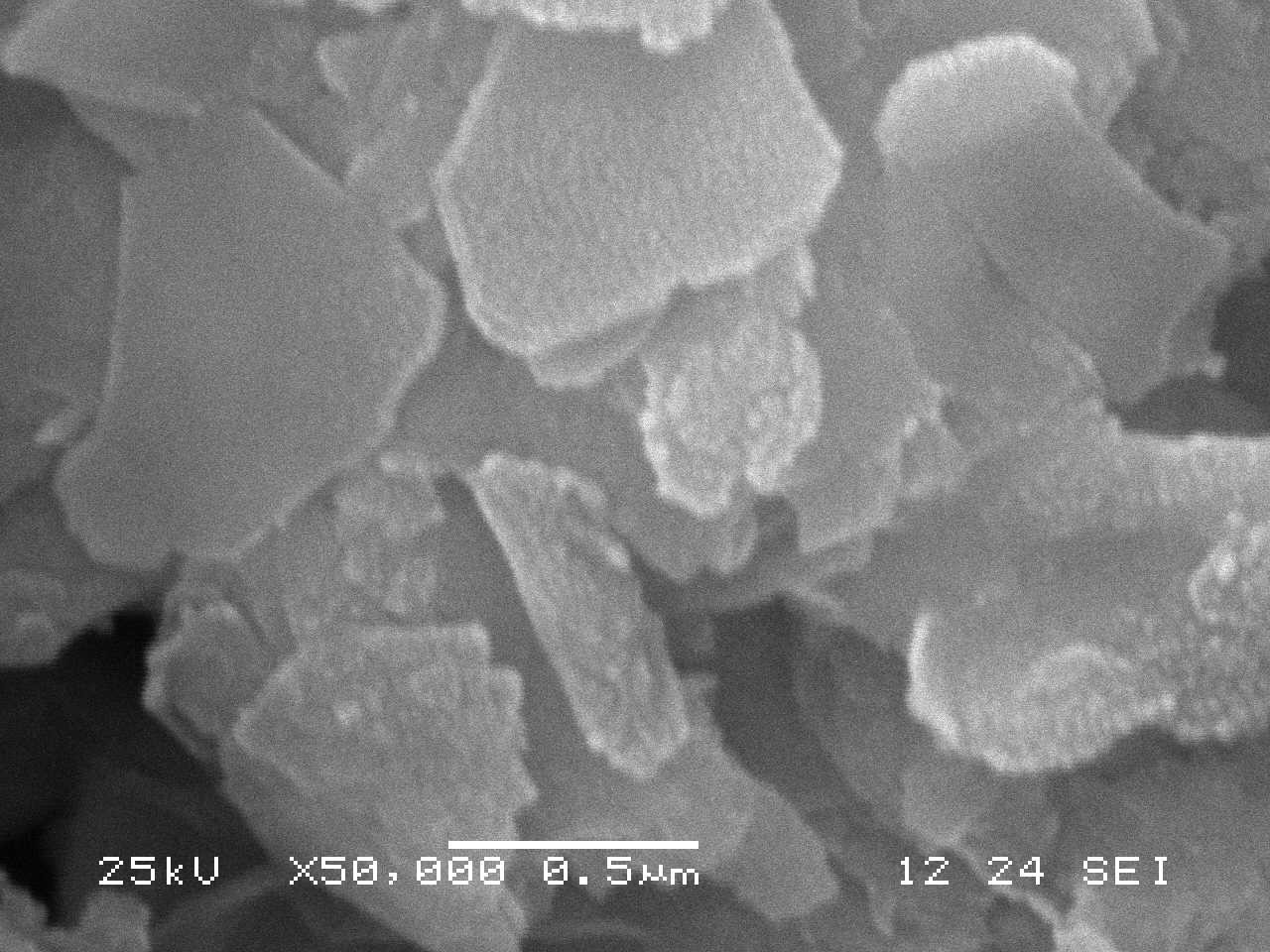

It is important to know what tungsten disulfide is before getting into its properties and uses. It is created by bringing together, through a chemical reaction, both tungsten and sculpture, which occur naturally. The result is a powder that can be easily mixed with adhesives and converted into a spray form. In this form, it should be applied to various metal surfaces from a distance, and it appears as an even coating. After this coating has been applied, it will stick to the surface normally and will not get wiped off due to water or other liquids that can corrode or dissolve coatings. Here is a look at the three key features WS2 Dry Lube:

• It is a dry, solid lubricant that is known for its highly lubricious nature.

• It has a lubrication ability that is unmatched by another substance, even graphite or molybdenum disulfide.

• It is widely used in high temperature and high pressure applications.

One of the key industries that make use of this dry lubricant is aerospace and aircraft, where internal parts of critical machinery are coated with it. As a result, they stay in perfect working condition for a long period of time. This dry lubricant is also used in the injection molding industry, where it effectively brings down the friction during the molding process.

One of the main reasons why tungsten disulfide is preferred over other lubricants is that it can show better performance upon application. As a result, in specialized heavy duty equipment such as that seen in the aerospace, automotive, and military industries, it is the best means of providing protection from rusting, fretting, and lubrication between moving parts.It also has a low coefficient of friction, so much so that it is able to provide superior lubrication to any other dry lubricant. After it is applied to a metal surface, there is no need to bake or cure it for tungsten disulfide to stick to the surface.